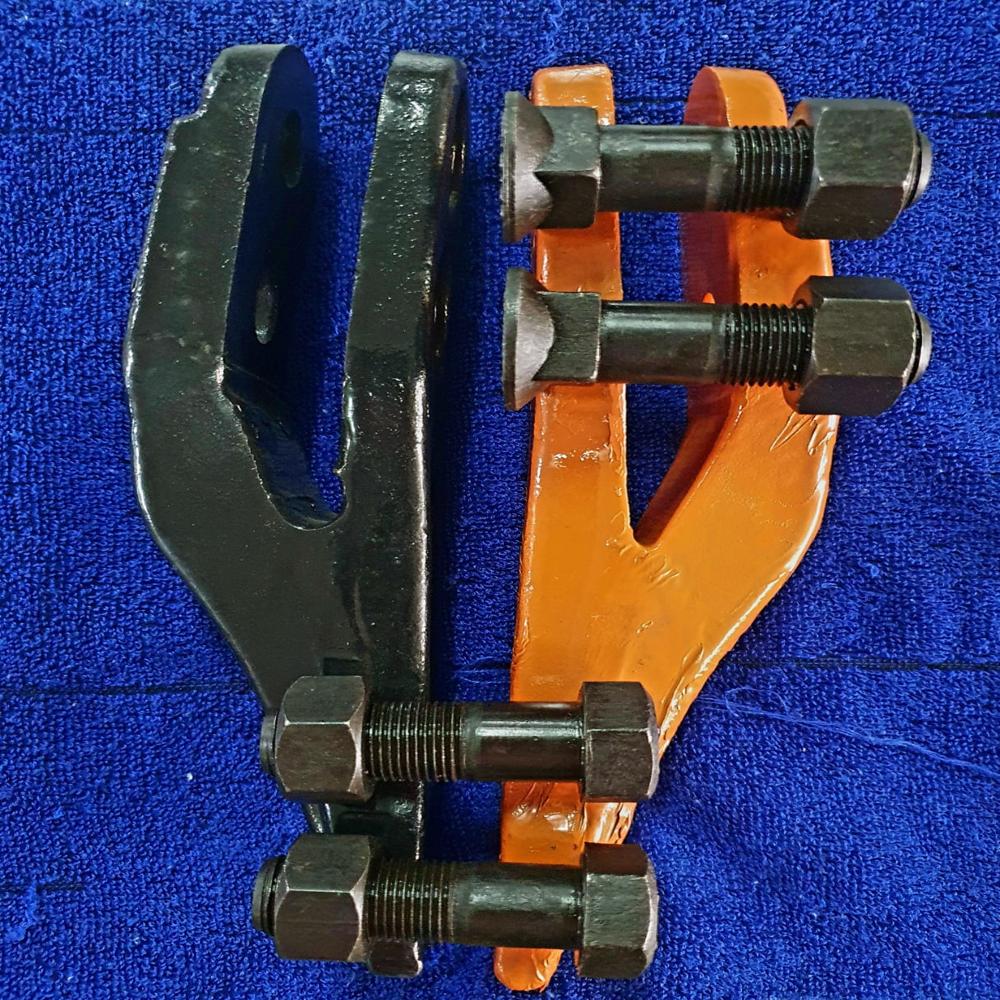

Bucket Loader Teeth Kit

Bucket Loader Teeth Kit Specification

- General Use

- Industrial

- Computerized

- No

- Automatic

- No

- Hydraulic Steering

- No

- Control System

- Manual

- Feature

- Environmental Friendly

- Warranty

- Yes

Bucket Loader Teeth Kit Trade Information

- Minimum Order Quantity

- 10 Sets

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1000 Sets Per Week

- Delivery Time

- 7 Days

- Sample Available

- No

- Packaging Details

- 8 TEETH + 16 BOLTS IN ONE KIT

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

- Certifications

- ZED

About Bucket Loader Teeth Kit

A bucket loader teeth kit is a set of replaceable teeth designed to be attached to a loader's bucket for enhanced digging and excavation capabilities. These kits are crucial for maintaining the efficiency and extending the lifespan of heavy machinery used in construction, mining, and other demanding applications.

- Teeth: High-strength alloy steel for superior wear resistance and durability.

- Adapter: The component that connects the teeth to the bucket.

- Pin: Secures the tooth and adapter to the bucket.

- Retainer: A component that holds the pin in place.

- Optimized digging performance.

- Easy installation and maintenance.

- Corrosion-resistant finish for increased durability in harsh working conditions.

- Application: Consider the type of work to be performed (general excavation, rock digging, trenching, etc.) to select the appropriate tooth design (standard, rock, tiger, etc.).

- Material: Different materials offer varying levels of hardness and toughness. Choose based on the materials being excavated and desired wear resistance.

- Compatibility: Ensure the kit is specifically designed for your loader's make, model, and bucket size for a proper fit and optimal performance.

- Mounting System: Select the mounting system (bolt-on or pin-on) that best suits your needs and machine specifications.

- Cost vs. Performance: Balance initial cost with long-term durability and performance benefits to maximize your investment.

Durable and Eco-Conscious Construction

Our Bucket Loader Teeth Kit is crafted with environmental responsibility in mind, using materials and processes that minimize ecological impact while maintaining high standards of industrial strength and longevity. This makes it the ideal choice for organizations looking to reduce their carbon footprint without compromising on performance.

Easy Manual Operation for General Use

This kit is purposely designed without automatic, computerized, or hydraulic steering systems, making it simple to operate and maintain. The manual control ensures reliability in all industrial applications, allowing seamless integration into existing equipment fleets.

Trusted Indian Manufacturer and Exporter

Sourced from reputable manufacturers within India, our Bucket Loader Teeth Kit is distributed, exported, and supplied globally. With support from experienced traders, you benefit from competitive pricing and consistent product availability.

FAQ's of Bucket Loader Teeth Kit:

Q: How do I install the Bucket Loader Teeth Kit on my equipment?

A: Installation is straightforward and requires only basic tools. Simply remove the worn-out teeth from your bucket loader and secure the new teeth from the kit, following the supplied manual instructions. No specialized experience or automatic systems are necessary.Q: What makes this Bucket Loader Teeth Kit environmentally friendly?

A: The kit is made using sustainable materials and eco-conscious manufacturing processes that reduce waste and emissions. This approach supports environmentally responsible industrial practices while ensuring robust product performance.Q: When should Bucket Loader Teeth typically be replaced?

A: It is advisable to replace loader teeth when they show significant wear, such as thinning, chipping, or reduced digging efficiency. Regular inspection based on your usage intensity will ensure optimal performance and prevent potential damage to the loader.Q: Where can I purchase the Bucket Loader Teeth Kit?

A: The kit is available through authorized distributors, exporters, manufacturers, suppliers, and traders based in India. You can contact these sources directly for bulk orders or export requirements.Q: What is the process for claiming warranty support?

A: In the event of a defect or premature failure, contact your supplier or manufacturer with proof of purchase and details about the issue. Warranty terms are clearly outlined at purchase, ensuring smooth claims and replacements if necessary.Q: How does the manual control system benefit industrial users?

A: A manual control system minimizes the risk of malfunction, is easier to repair, and reduces reliance on complex electronics or hydraulics. This keeps maintenance costs low and makes the equipment suitable for rugged industrial conditions.Q: What advantages does this kit offer over automated or computerized loader teeth kits?

A: This kit's manual design prioritizes durability and ease of use, particularly in environments where technical resources are limited. It does not require any specialized training or electronic components, making it practical and cost-effective for industrial applications.

Price 400.0 INR/ Set

- Minimum Order Quantity

- 10 Sets

- Supply Ability

- 1000 Sets Per Week

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

- Main Export Market(s)

- Asia

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Earthmoving Machinery Parts Category

Front Wheel Hub

Minimum Order Quantity : 10 Pieces

Cooling System : Air Cooling

Color : Silver

Material : Stainless Steel

Warranty : 12 Month

Hydraulic Steering : Yes

Washer For JCB Hitachi

Minimum Order Quantity : 10 Pieces

Cooling System : Air Cooling

Color : Silver

Material : Stainless Steel

Warranty : 12 Month

Hydraulic Steering : Yes

Rear Joint Strap

Minimum Order Quantity : 10 Pieces

Cooling System : Air Cooling

Color : Copper

Material : Aluminum

Warranty : 6 Month

Hydraulic Steering : Yes

Teeth Bolt With Nut

Minimum Order Quantity : 10 Pieces

Cooling System : Air Cooling

Color : Black

Material : Stainless Steel

Warranty : 12 Month

Hydraulic Steering : Yes

Send Inquiry

Send Inquiry Send SMS

Send SMS